Small

Image

Disable image alteration

Off

Off

Lithium

One column

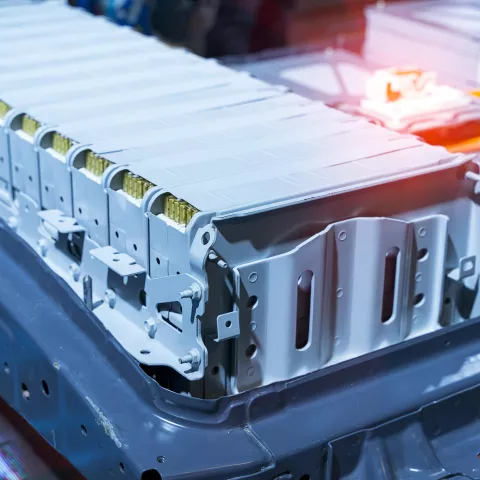

Lithium applications

Lime, also known as quicklime, plays a crucial role during the processing of solution brines and mineral ores to produce lithium carbonate and lithium hydroxide, which are vital to produce rechargeable batteries used in electric vehicles and various electronic devices. Additionally, lime is instrumental in the manufacture of lithium used in ceramics, glass, greases, and metallurgical powders.

Open cta in a new tab

Off

Background Grey

Off

One column

As an indispensable reagent, lime, also know as quicklime, is used in numerous lithium process flow sheets that treat a variety of raw feed materials, such as:

- Spodumene concentrate, processed either through the acidic roast method (using H2SO4) or the alkaline pressure leaching technique (employing Na2CO3).

- Brines sourced from lithium salars, geothermal plants, or oil field operations.

- Lithium-enriched clays, micas, and borates.

- Lithium carbonate, typically, technical-grade lithium carbonate.

Open cta in a new tab

Off

Background Grey

Off

One column

The typical applications of lime/quicklime reagents within lithium process flow sheets encompass:

- Impurity removal, including dissolved magnesium, silicon, aluminum, and iron. Removal of such impurities is a prerequisite for subsequent lithium purification stages.

- DLE (direct lithium extraction) pH control, where lime is utilized to maintain the pH within the DLE adsorption or ion exchange process units at an optimal level, thereby maximizing performance efficiency.

- The conversion of lithium carbonate to lithium hydroxide

- Flue gas treatment of HF, HCl, Hg and/or SO2 generated in high temperature calcination and roasting process steps.

Open cta in a new tab

Off

Background Grey

Off

One column

Open cta in a new tab

Off

Background Grey

Off

Non ferrous

Non ferrous